Advanced Manufacturing Techniques

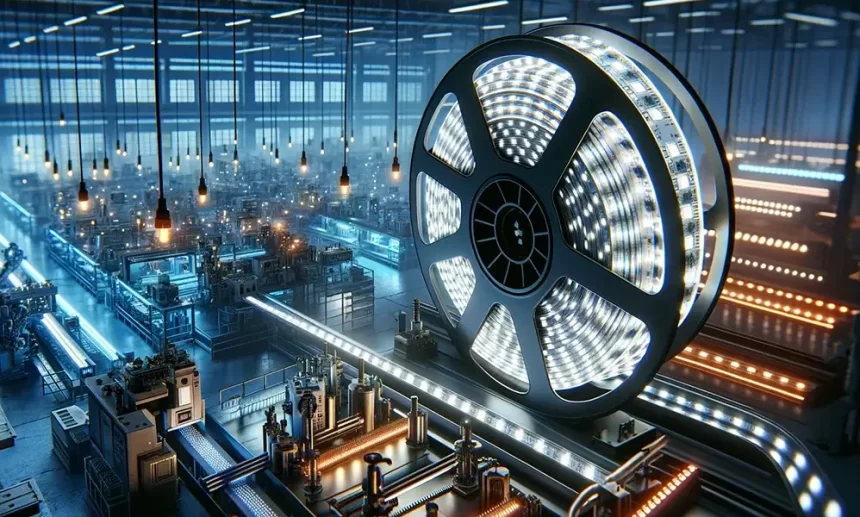

LED strip light factories are revolutionizing their manufacturing processes by incorporating advanced robotics and automation technology. These changes have dramatically increased production speeds and consistency, allowing for the output of up to 10,000 meters of LED strips per day in top facilities. The integration of automatic cutting machines and precision placement systems ensures each strip is made to exact specifications with minimal waste.

Enhanced LED Technology

The push towards more efficient and powerful LEDs has led factories to develop chips that are not only brighter but also consume less power. Recent advancements have seen the creation of LEDs capable of producing up to 180 lumens per watt, a significant increase from the 100 lumens per watt that was standard just a few years ago. These improvements extend the lifespan of LED strips, now lasting up to 50,000 hours, and reduce the energy consumption, making them more eco-friendly.

Smart Connectivity

Incorporating IoT (Internet of Things) technology, LED strip light factories are making strides in the smart home industry. Modern LED strips can be controlled via smartphone apps, voice commands through home assistants like Amazon Alexa or Google Assistant, and even integrate with other smart home systems for seamless automation. This connectivity offers users unprecedented control o

Customization and Flexibility

To meet diverse consumer needs, factories are now offering highly customizable LED strips. Customers can specify the color temperature (measured in Kelvin), color rendering index (CRI), and even the exact length of their LED strips to the nearest centimeter. These customization options empower users to tailor lighting solutions to their specific environment and aesthetic preferences.

Eco-Friendly Materials

Today’s LED Strip Light factory places a strong emphasis on sustainability. Newer models of LED strips use recyclable materials and are designed to be free from harmful chemicals like lead and mercury. Additionally, the move towards solvent-free adhesives and recyclable packaging further reduces the environmental footprint of these products.

Enhanced Waterproofing Techniques

For outdoor and industrial applications, LED strip lights need to withstand various elements. Innovations in waterproofing technology have led to the development of strips that are completely encapsulated in silicone, offering IP68 protection, which means they are dust-tight and can be submerged in water indefinitely. This advancement opens up new possibilities for outdoor and underwater lighting designs.

Increased Market Reach

Factories are also expanding their market presence by adapting their products for new applications beyond traditional home and commercial spaces. LED strips are now being used in automotive lighting, signage, art installations, and even in agricultural settings to enhance plant growth. This versatility has opened up new revenue streams and broadened the consumer base for these innovative lighting solutions.

Enhanced LED Technology

The push towards more efficient and powerful LEDs has led factories to develop chips that are not only brighter but also consume less power. Recent advancements have seen the creation of LEDs capable of producing up to 180 lumens per watt, a significant increase from the 100 lumens per watt that was standard just a few years ago. These improvements extend the lifespan of LED strips, now lasting up to 50,000 hours, and reduce the energy consumption, making them more eco-friendly.

These innovations underline the dynamic nature of the LED strip lighting industry and highlight how LED Strip Light Wholesale are continually pushing the boundaries to offer better, smarter, and more sustainable lighting solutions.